Кварцевый гибкий акселерометр: идеальный выбор для высокоточного мониторинга в аэрокосмической и оборонной промышленности.

Compared with traditional accelerometers, quartz flexible accelerometers have higher accuracy and reliability. Its high precision can be reflected in the accuracy of data, while its reliability can be reflected in the stability and lifespan of equipment operation. In addition, due to the insensitivity of quartz crystals to temperature and time changes, quartz accelerometers are also more capable of ensuring long-term and stable operation than other accelerometers. Quartz flexible accelerometers have become core sensors in aerospace, defense, industrial monitoring, and other fields due to their ultra-high precision, strong impact resistance, and extreme environmental adaptability.

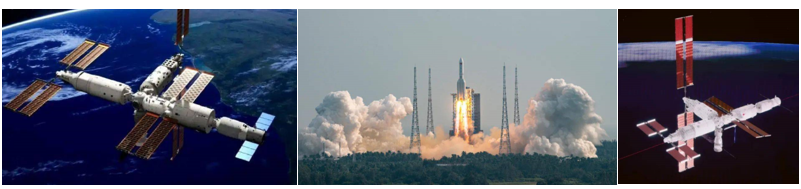

In spacecraft docking missions, quartz accelerometers are used to detect μg (microgravity) level acceleration, providing real-time velocity increment and attitude adjustment data to ensure docking accuracy. When the spacecraft returns to the atmosphere, it needs to withstand a high overload of 3-5g while maintaining measurement stability.

When used for satellite attitude adjustment and rocket launch monitoring tasks, quartz flexible accelerometers can achieve an accuracy of 60 μg with zero bias repeatability and withstand 1000g instantaneous impact (such as rocket separation). Meanwhile, the quartz flexible accelerometer can provide gravity field data for the lander, supporting precise soft landing.

In space microgravity experiments, quartz flexible accelerometers are used to measure the six degree of freedom motion of loads, with an accuracy of "observing hair falling to the ground" level to eliminate vibration interference.

The inertial navigation system of long-range ballistic missiles and tactical missiles relies on quartz accelerometers to maintain scale factor stability (<30ppm) in impact environments of 500-1000g, ensuring ballistic accuracy. For example, it needs to withstand 100g/5ms half sine wave impact, which is suitable for high overload at the moment of missile launch.

In the application of armored vehicles and drones, the stability control of tanks and armored vehicles needs to continuously output reliable data in a vibration environment (20-2000Hz random vibration). The drone navigation system utilizes the low-power (<480mW) and lightweight (<65g) characteristics of quartz flexible accelerometers to extend range and enhance maneuverability.

Quartz accelerometers are applied in monitoring landslides and debris flows, capturing surface micro deformations with a resolution of μg to achieve early geological hazard warning.

In deformation monitoring of bridges and high-speed railways, quartz flexible accelerometers can provide long-term stability (monthly drift<50 μg) and reduce maintenance costs.

In the field of energy exploration, oil drilling measurement systems (such as wireless inclinometers) rely on their high temperature resistance (185℃) to provide inclination data in high-pressure impact environments underground.

The core advantages of quartz flexible accelerometers lie in their ultra-high accuracy and long-term stability, with scale factor drift reaching ppm level and zero bias stability reaching μg/√h level. Taking the AC-3 series quartz flexible accelerometer produced by Micro-Magic Inc as an example:

|

Parameters |

AC-3A |

AC-3B |

AC-3C |

Unit |

|

Threshold /Resolution |

5 |

5 |

5 |

μg |

|

Bias drift (1σ, one month) |

≤15 |

≤50 |

≤50 |

μg |

|

Repeatability of scale factor (1σ, one month) |

≤15 |

≤50 |

≤50 |

ppm |

|

Bias thermal coefficient |

≤ ±15 |

≤ ±50 |

≤ ±50 |

μg/℃ |

|

Scale factor thermal coefficient |

≤ ±15 |

≤ ±80 |

≤ ±50 |

ppm/℃ |

Quartz flexible accelerometers have excellent impact resistance. Its high hardness fused silica integrated structure and frictionless flexible design enable it to withstand 1000g/0.5ms half sine impact, which is far superior to ordinary MEMS sensors. Taking the AC-4 series products produced by Micro-Magic Inc as an example:

|

Parameters |

AC-4A |

AC-4B |

AC-4C |

Unit |

|

Shock |

500g |

1000g |

1000g |

0.5ms, 1/2sin |

|

Vibration peak sin (@30~500Hz) |

25 |

25 |

25 |

g |

Quartz flexible accelerometers exhibit excellent environmental adaptability over a wide temperature range, such as . The extremely low thermal expansion coefficient and symmetrical structure of quartz material result in minimal temperature drift (as low as ppm/° C), making it a reliable choice for high-precision measurement in extreme temperature environments such as aerospace and military. Taking the AC-6 series products produced by Micro-Magic Inc as an example:

|

Parameters |

AC-6A |

AC-6B |

Unit |

|

Bias thermal coefficient |

≤ ±80 |

≤ ±150 |

μg/℃ |

|

Scale factor thermal coefficient |

≤100 |

≤200 |

ppm/℃ |

|

Temperature range (Operating) |

-40 ~ +150 |

-40 ~ +150 |

℃ |

|

Temperature range (Saved) |

-60 ~ +180 |

-60 ~ +180 |

℃ |

With its excellent precision, outstanding long-term stability, and outstanding resistance to extreme environments, quartz flexible accelerometers have firmly established their position as the core device for precise monitoring in the aerospace and military industry. It plays an irreplaceable key role in high-precision inertial navigation, aircraft attitude control, and various precision measurement tasks.

Xml политика конфиденциальности блог Карта сайта

Авторское право

@ Микро-Мэджик Инк Все права защищены.

ПОДДЕРЖИВАЕМАЯ СЕТЬ

ПОДДЕРЖИВАЕМАЯ СЕТЬ