Применение инерциальных измерительных блоков (ИМБ) на основе микроэлектромеханических систем (МЭМС) в промышленности в основном сосредоточено на высокоточном управлении движением, мониторинге оборудования и автоматизированном производстве. Выбор подходящего МЭМС ИТБ для промышленного применения требует всестороннего учета точности, адаптации к условиям окружающей среды, совместимости интерфейсов и экономической эффективности.

Применение MEMS IMU в области промышленных роботов и автоматизации в основном сосредоточено на обратной связи и управлении ориентацией, навигации AGV/AMR, а также мониторинге и диагностике вибраций. В приложениях для обратной связи и управления ориентацией MEMS IMU предоставляет информацию об ориентации (тангаж, крен, рыскание) и угловой скорости в реальном времени для шарниров робота, концевых эффекторов или мобильных платформ, обеспечивая точное управление движением, планирование траектории и предотвращение столкновений. В приложениях для навигации AGV/AMR MEMS IMU интегрируется с датчиками скорости вращения колес, LiDAR и визуальными датчиками для обеспечения функции инерциальной навигации. При временной потере внешнего ориентира IMU может поддерживать кратковременное позиционирование и направление, повышая надежность и непрерывность навигации. В приложениях для мониторинга и диагностики вибраций MEMS IMU устанавливается на шарнирах робота, ключевых конструкциях или двигателях для мониторинга спектра и амплитуды вибраций во время работы, для прогнозирующего технического обслуживания и для раннего выявления неисправностей, таких как износ подшипников, дисбаланс и смещение.

Требования к инерциальным измерительным блокам MEMS в области промышленных роботов и автоматизации в основном сосредоточены на следующих аспектах:

Стабильность нулевого смещения является наиболее важным показателем статической производительности, а низкая стабильность нулевого смещения означает, что долговременная точность оценки ориентации (тангаж, крен, рыскание) имеет решающее значение. Когда роботы работают в течение длительного времени или автоматизированные транспортные средства (AGV) точно перемещаются, низкий дрейф нулевого смещения является ключевым фактором обеспечения точности ориентации. Стабильность нулевого смещения гироскопов обычно требует <1°/ч, а для высокотехнологичных применений требуется <0,5°/ч. Индекс стабильности нулевого смещения акселерометров требует <1 мг. Кроме того, случайное угловое блуждание отражает характеристики белого шума на выходе гироскопа, что определяет скорость увеличения ошибки интегрирования угла с течением времени. Низкое значение ARW является основой для достижения высокоточной ориентации, особенно за короткий промежуток времени, и особенно важно для управления движением высокоскоростных и высокодинамичных роботов.

В качестве примера рассмотрим высокопроизводительные MEMS-инерциальные измерительные блоки (IMU) серий U6300 и U7000 от Micro-Magic Inc.:

Указательный пункт | U6300-A | U6300-D | U7000 | Единица | |

Гиро | Нестабильность смещения | 0,5 | 0.1 | 0.1 | °/ч |

Случайное блуждание | 0,02 | 0,05 | º/√час | ||

Стабильность при нулевом смещении (10 с) | 1 | 3 | °/ч | ||

Аккл | Нестабильность смещения | 10 | 15 | μg | |

Случайное блуждание | 0,02 | 0,01 | м/с/√ч | ||

Стабильность при нулевом смещении (10 с) | 100 | 100 | μg | ||

Частота движений суставов промышленных роботов высока, а частота вибрации на конце роботизированной руки может быть еще выше. Высокая полоса пропускания имеет решающее значение для точного захвата быстрых движений и вибраций. Обычно полоса пропускания должна превышать 100 Гц, а то и сотни Гц. Кроме того, роботы могут быстро начинать и останавливаться, сталкиваться, а автоматизированные транспортные средства (AGV) могут передвигаться по неровным дорогам. Перегрузка может вызвать искажение данных из-за насыщения, поэтому от MEMS-инерциальных измерительных блоков (IMU) требуется достаточно широкий диапазон. Как правило, для гироскопов может потребоваться диапазон ± 300°/с до ± 2000°/с или выше, а для акселерометров — от ± 2g до ± 50g или выше.

Рассмотрим в качестве примера продукты U3600, U5000 и U6488 от компании Micro-Magic Inc.:

Указательный пункт | U3600 | U5000 | U6488 | Единица | |

Гиро | Диапазон | ±2000 | ±400 | ±450 | °/с |

Полоса пропускания 3 дБ | 116 | 250 | 400 | Hz | |

Аккл | Диапазон | ±12 | ±10 | ±20 | g |

Полоса пропускания 3 дБ | 145 | 100 | 268 | Hz | |

В промышленной среде много вибраций (двигатели, шестерни, конвейерные ленты и т. д.). Инерциальный измерительный блок (IMU) должен уметь подавлять эти вибрационные помехи и избегать выдачи ошибочных данных (особенно гироскопы, чувствительные к линейным вибрациям и генерирующие ошибки, чувствительные к перегрузкам). Необходимы качественная механическая конструкция (например, демпфирование) и передовые алгоритмы обработки сигналов. Необходимо обеспечить сохранность оборудования и предотвратить необратимое ухудшение его характеристик при неожиданных столкновениях, падениях или сильных ударах. Обычно оно должно выдерживать удары с перегрузками в тысячи g.

Рассмотрим в качестве примера продукцию U3500, U3600 и U3700 от компании Micro-Magic Inc.:

Указательный пункт | U3500 | U3600 | U3700 |

Антивибрационная система(g,Рмс) | 1,0 мм (10 Гц-58 Гц) и ≤20 г (58 Гц-600 Гц) | ||

Шок(g) | 2000, <1 мс | ||

защита окружающей среды | Директива RoHS 2011/65/EU | ||

ЭМС | Директива LVD 2014/35/ЕС | ||

тест на падение | Трижды свободное падение с экспериментальной платформы высотой 75 см. | ||

Температурный шок | Повысить температуру с -40 до 85 ℃ в течение 1 часа, 5 раз. | ||

Благодаря своим малым размерам, небольшому весу и низкому энергопотреблению, инерциальные измерительные блоки MEMS (IMU) все шире используются в промышленности и военной сфере. Миниатюризация позволяет легко встраивать IMU в шарниры роботов, концы звеньев, компактные корпуса автоматизированных транспортных средств (AGV) и даже внутренние части инструментов без существенной нагрузки или изменений в конструкции; облегченная конструкция минимизирует влияние IMU на грузоподъемность и характеристики движения роботов, особенно высокоскоростных, высокоточных или коллаборативных роботов; низкое энергопотребление IMU продлевает срок службы батарей мобильных роботов и беспроводных сенсорных узлов, снижая общее энергопотребление и требования к теплоотводу системы.

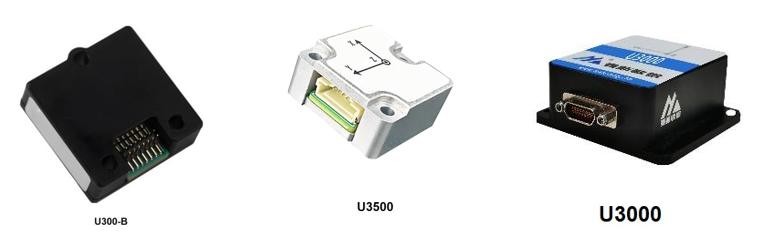

Рассмотрим в качестве примера продукцию U300, U3500 и U3000 от компании Micro-Magic Inc.:

Указательный пункт | U300-B | U3500 | U3000 | Единица |

Измерение | 22.4*22.4*7.4 | 22*22*10 | 59.6*59*23.5 | mm |

Масса | 7 | 8 | 120 | g |

Потребление электроэнергии | 0.3 | 0.3 | 0,6 | W |

Напряжение | 3.3 | 3.3 | 5 | V |

Промышленные MEMS-инерциальные измерительные блоки (IMU) должны обеспечивать высокий уровень баланса по этим строгим показателям, чтобы соответствовать комплексным требованиям современных промышленных роботов и систем автоматизации в отношении точности восприятия, надежности, работы в реальном времени и отказоустойчивости.

Xml политика конфиденциальности блог Карта сайта

Авторское право

@ Микро-Магия Инк Все права защищены.

ПОДДЕРЖИВАЕМАЯ СЕТЬ

ПОДДЕРЖИВАЕМАЯ СЕТЬ